REFERENCE

Stud bolts for high pressure & high temperature applications conform to the requirements of ANSI/ASME B16.5, Steel Pipe Flanges and Flanged Fittings.

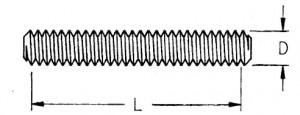

LENGTH-FIRST TO FIRST

The length of stud bolt, measured parallel to the axis, is the distance from first thread to first thread. First thread is defined as the intersection of the major diameter of the thread with the base of the point. Please see the drawing above-this is confusing to most users!! Stud bolts are normally available from stock in 1/4 inch length increments. Length tolerances, all stud bolt sizes, shall be as tabulated below:

Length, in. Length Tolerance, in.

to 12 +/-0.062

over 12 to 18 +/-0.125

over 18 +/-0.250

POINTS

Points shall be flat and chamfered, or sheared at option of the manufacturer. When points are flat and chamfered, the diameter of the flat shall not exceed the minor diameter of the thread, and shall be not less than one or more than two complete threads as measured from the extreme end parallel to the axis.

THREADS

Threads shall be Unified inch coarse thread series (UNC), Class 2A, for all stud bolt sizes 1 in. and smaller, and Unified inch 8 thread series (8 UN), Class 2A, for all stud bolts larger than 1 in., in accordance with ANSI/ASME B1.1. Acceptability of screw threads shall be determined based on ANSI/ASME B1.3.

MATERIAL

Chemical and mechanical requirements shall be specified by the purchaser and shall be in accordance with applicable ASME, ASTM, and ANSI codes and specifications current at the time of ordering.

ASTM Material Selection Chart – Stud bolas are available in ASTM A193 Grade B7, B7M, L7, L7M. As well as 660, 718 Inconel, Mp35N and other high nickel alloys and stainless steels.

DESIGNATION

It is recommended that stud bolts be designated in the following sequence: product name, nominal size, threads per inch, length, material, and protective finish, if required.

Example: ANSI/ASME B16.5 stud bolt,

5/8-11 x 3-1/2, ASTM A193, Grade B7, Zinc & Clear Chromate Plated