ASME B16.47 and B16.5 Flange Bolts: Ensuring Secure Connections

In industrial engineering and construction, where the integrity of connections is paramount, ASME B16.47 and B16.5 flange bolts stand as stalwart guardians of safety and reliability. These standards, developed by the American Society of Mechanical Engineers (ASME), delineate the specifications for flanges and flanged fittings, crucial components in pipelines, pressure vessels, and various mechanical systems.

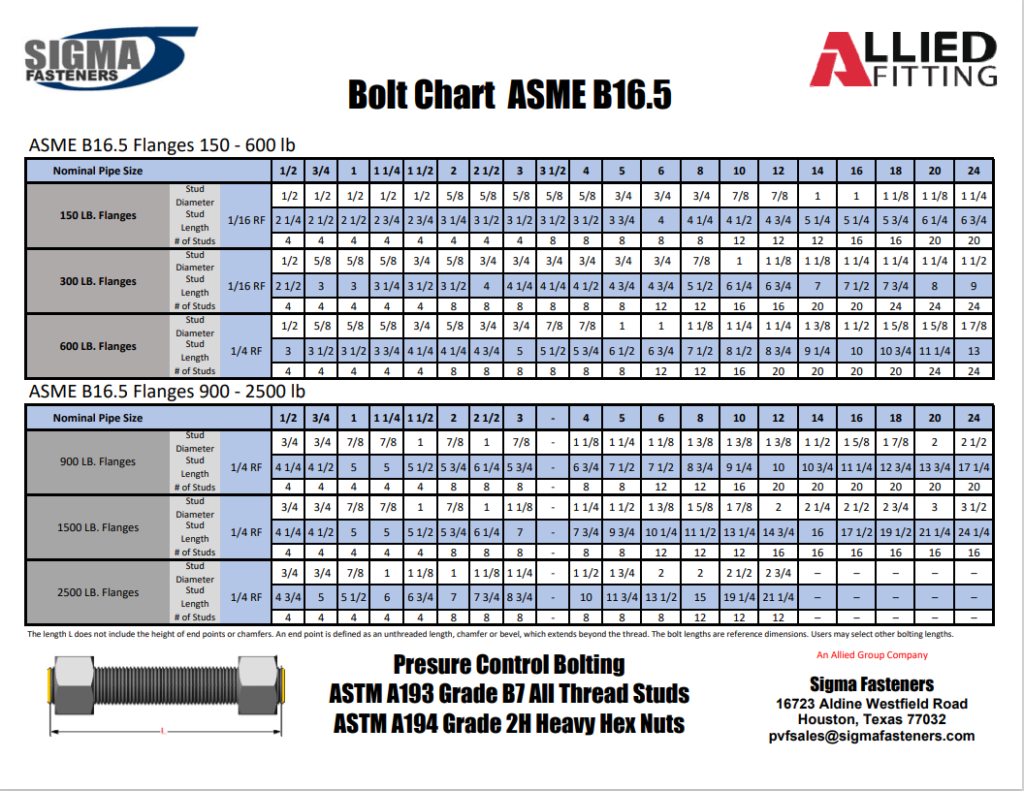

Flange bolts are pivotal in ensuring the structural integrity of flange connections, and they are ubiquitous in industries ranging from oil and gas to chemical processing. ASME B16.5 covers flanges up to 24 inches nominal pipe size, while B16.47 extends the range up to 60 inches. Both standards provide detailed guidelines for flanges’ dimensions, materials, testing procedures, and associated bolts.

One of the critical aspects of these standards is the meticulous attention given to bolt dimensions and thread specifications. Flange bolts must meet stringent criteria to ensure proper engagement and load distribution, preventing leaks, spills, and catastrophic failures. Moreover, materials for these bolts are carefully selected to withstand the harsh conditions prevalent in industrial environments, including corrosion, high temperatures, and pressure fluctuations.

Beyond their technical specifications, ASME B16.47 and B16.5 flange bolts symbolize a commitment to safety and quality in engineering practices. Compliance with these standards not only fosters interoperability and consistency but also instills confidence in the reliability of industrial systems. As industries evolve and face new challenges, adherence to established standards remains a cornerstone of responsible engineering, ensuring that flange connections uphold the highest performance and safety standards.

Download Flange Bolt Chart