ISO 9001:2015 Certified

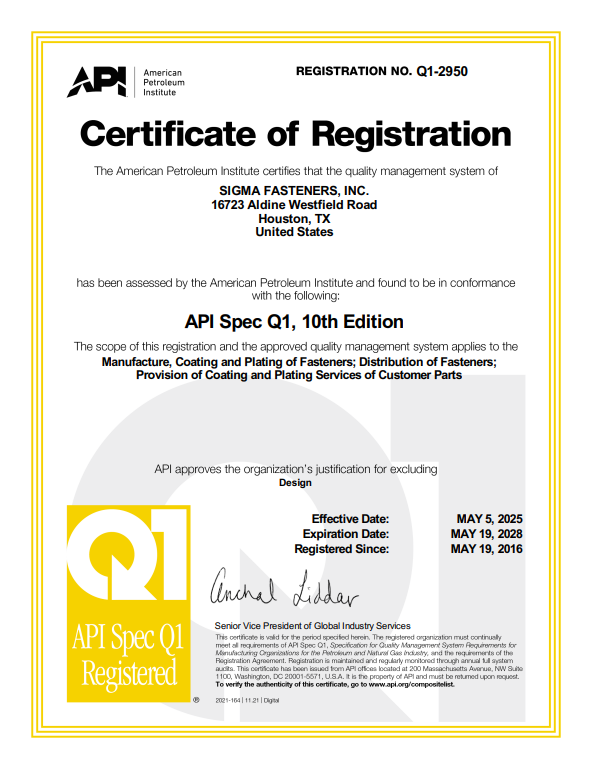

Sigma Fasteners has been independently audited and certified to be in conformance with ISO 9001:2015 ISO Certification as registered by Lloyds Register Quality Assurance. Sigma is also

certified to API Specification Q1. The scope of the registration applies to the manufacture and distribution of fasteners, coating, and plating of customer parts for the oil and gas industries. Sigma also holds an American Petroleum Institute Monogram Licenses to manufacture API 20E BSL 3 & API 20F BSL 3 bolting.

American Petroleum Institute Monogram Licenses API 20E-0017 and API 20F-0007

API 20E BSL 1, BSL 2, BSL 3

API 20F BSL 2, BSL 3

Quality Statement

Culture of continuous improvement

“Continuous improvement”, is a mentality that every Sigma employee possesses. The management of Sigma Fasteners creates a climate in which

improvements be suggested by everyone in the organization. Open communication is the condition for recognizing the most important issues and implementing solutions.

Striving for zero faults

In each phase of production of our product, the work must be done right. Inspection of products is based on random tests. Prevention is better than reaction; this is the only approach to achieving zero faults. Quality is guaranteed by ensuring that processes remain within well-defined procedures. When taking orders, specifying work orders and job routers customer specifications and industry standards are taken into account. To a large extent, the training and knowledge of the employees determine the success of the policy of striving for zero faults. Short and longer training courses play a key role in keeping their knowledge and ability up to speed.

Reliable Delivery

Sigma strives to meet the delivery times agreed upon with customers. Sigma’s delivery reliability is measured each week. All employees are contentious of due dates and strive to meet internal and customer deliveries.

Links to Current Certificates: