Xylan Industrial Coating Service

Xylan coating prevents leaks past thread

Pressure vessels, valves, pipe unions, storage tanks, reactors, pipelines and other fluid containment equipment are often fitted with threaded plugs for inspection, pressure relief, filling or tapping.

Coatings on pipe plugs not only improve their performance and reliability but also make them easier to use. A thin film of Xylan eliminates the PTFE tape normally wrapped around the threads to seal them.

In addition, the corrosion protection and low-friction properties of the coating greatly reduce breakout torques, enabling users to remove the plugs at a later date without destroying them.

In most instances, the pipe plugs may be re-used without difficulty.

Xylan coatings are also available in many colors, enabling users to color-code particular plug sizes and alloys.

Xylan 1014

Main Properties:

High temperature resistant. Low coefficient of friction. Abrasion / wear resistant. Dry film lubricant. Thermoset. Wide use temperature.

Typical Applications: Any mating surface which requires lubrication. Hinge pins. Piston casing. Compressors. Fasteners.

Description: Resin-bonded, thermosetting, dry-film lubricant which, when compared to Xylan 1010 contains significantly more bonding resin relative to its content of PTFE lubricant. Altering the formula in this manner produces finishes which are harder, more abrasion resistant, glossier, and less porous. Frictional values remain low and very predictable.

Working temp. range (continuous) -195°C/-320°F to 260/500°F Working temp. range (intermittent) -195°C/-320°F to 285°C/545°F

Xylan 1052

Main Properties:

High temperature resistant. High load carrying capacity. Abrasion / wear resistant. Thermoset.

Typical Applications: Applications to prevent wear of mating surfaces under extreme load such as bearings, sealing rings, and valve springs.

Main Properties:

High temperature resistant. Low coefficient of friction. Abrasion / wear resistant. Thermoset. Wide use temperature. Corrosion resistant. Controlled torque.

Typical Applications: Threaded fasteners.

Description: Resin-bonded, thermosetting, dry film lubricant. It is formulated for high-pressure, low-speed wear applications and provides long-term lubrication for bearing surfaces subjected to extreme pressures, up to 150,000 psi (10,500 kg/cm2). The coating utilizes a unique dual lubrication system of PTFE and MoS2 and is superior to moly greases which wash away and PTFE coatings which cold flow. Resin-bonded lubricants in Xylan 1052 stay on the job, even in harsh chemical environments.

Working temp. range (continuous) -195°C/-320°F to 260°C/500°F Working temp. range (intermittent) -195°C/-320°F to 285°C/545°F

Xylan 1070

Main Properties:

High temperature resistant. Low coefficient of friction. Abrasion / wear resistant. Thermoset. Wide use temperature. Corrosion resistant. Controlled torque.

Typical Applications: Threaded fasteners.

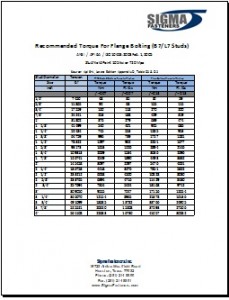

Description: Resin-bonded, thermosetting, PTFE based, dry-film lubricant. It has extra corrosion protection and issued to coat large studs (B7), nuts, flanges, and related hardware for sub-sea and splash-zone service. Because of its predictable, low-friction properties, less make-up torque is required to produce the specified tension. During assembly, clamp loads are increased; scatter is reduced. In fact, the frictional characteristics are the most predictable of any lubricant, coating, or plating used on bolting. The low friction properties also reduce break-out torque, which allows removal of bolting with a wrench instead of a blowtorch.

Application: Conventional spray.

Working temp. range (continuous) -195°C/-320°F to 260°C/500°F

Working temp. range (intermittent) -195°C/-320°F to 285°C/545°F

Xylan 1400

Main Properties:

Corrosion resistant. Chemical resistant. Weathering resistant. Acid rain resistant.

Typical Applications: Threaded fasteners for the building, chemical process, oil and off shore industries.

Description: A recoatable “RC” coating developed to protect large fasteners and chemical processing equipment from chemical exposure (especially those with high pH). Although it contains a small percentage of PTFE lubricant to facilitate installation and prevent galling, it is considered a barrier coating rather than a dry film lubricant.

Working temp. range (continuous) -50°C/-58°F to 175°C/350°F

Xylan 1424

Main Properties:

Dry film lubricant. Corrosion resistant.

Typical Applications: Any mating surface which requires lubrication. Hinge pins. Piston casing. Compressors. Threaded fasteners. Description: This VOC compliant*, resin-bonded, PTFE based coating is primarily formulated for use on fasteners to prevent corrosion and facilitate make-up torque.

Working temp. range (continuous) -50°C/-58°F to 175°C/347°F

Working temp. range (intermittent) -50°C/-58°F to 200°C/392°F

More Xylan Inforamation